Lightweight composite battery box for innovative electric vehicle

Lightweight composite battery box for innovative electric vehicle

D2H Advanced Technologies was tasked with designing a new battery box for an American EV manufacturer developing their latest electric vehicle, with strict targets for both weight and rigidity.

The result drew on our extensive knowledge of lightweight composite materials, as well as our experience with battery packs and cooling requirements, to deliver a solution that surpassed all key targets.

The existing battery box had been a conventional design fabricated from aluminium that weighed 150kg without the batteries. The challenge was to create a new design that weighed no more than 110kg, had enhanced stiffness to reduce its susceptibility to resonant frequencies that could negatively impact NVH, and maintained structural and electrical integrity even in the event of an accident.

The original component’s form factor, defined by the vehicle installation, was re-engineered for construction in lightweight composite materials, a process that required performing multiple Finite Element Analysis (FEA) simulations to optimise the proposed design.

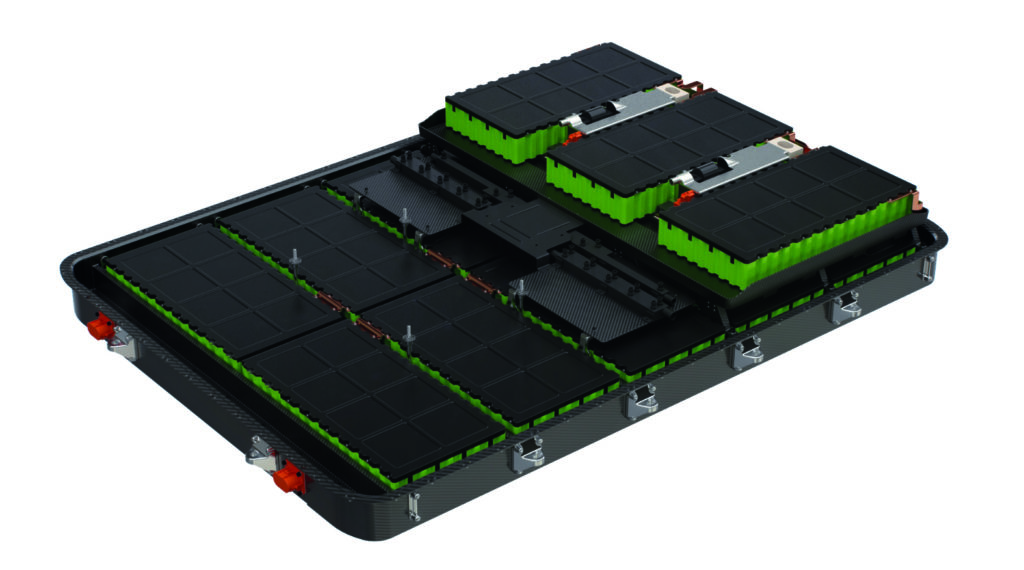

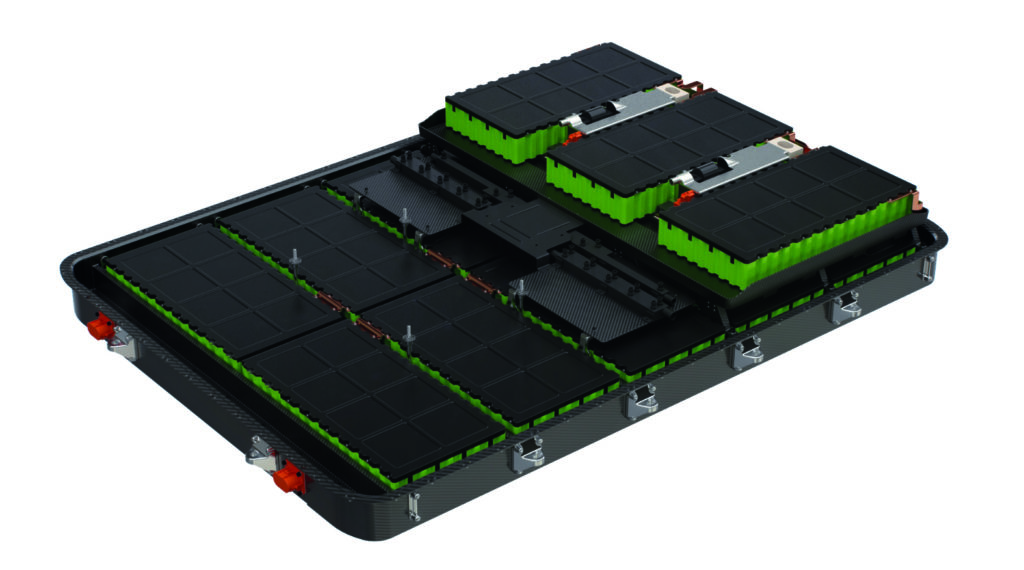

The project called for a stepped, twin-deck design to maximise the available space and therefore battery capacity. Thirteen battery modules could be accommodated within the pack, with dedicated space and mountings for the necessary wiring, battery management modules, and ancillaries. Ports for both liquid and filtered-air cooling systems were incorporated, with integral cold plates to maintain the battery cells’ temperature.

By using a hybrid laminate of carbon fibre and electrically-safe E-glass fibre combined with core materials, we were able to create a multi-ply construction that offered the strength, stiffness and weight efficiency of carbon fibre combined with the non-conductive isolation required around key electrical components and connections. Careful selection of varying carbon fibre materials allowed us to increase stiffness in key areas and precisely fine tune the completed assembly’s frequency response, thereby avoiding mechanical resonance.

Lightweight materials such as Rohacell® foam, Nomex® and aluminium honeycomb were used for many of the internal structures, increasing the stiffness of the component in the most weight-efficient manner.

The result was a new composite battery box that retained the required form factor, was stiffer and highly tolerant of vibrations, yet weighed significantly less than the original component. In fact, although the client had set a target of 110kg, we were able to deliver a completed assembly that weighed just 88kg, achieving a saving of more than 60kg over the original component.

By working closely with the client’s preferred manufacturing partner, we were able to ensure the final design met cost requirements as well as the performance needs, with additional assistance provided with tooling design.

.

““Weight can be a crucial factor in EV design, with every extra kilogram incurring a cost in terms of reduced overall range. Asking for a 40kg weight saving on a battery box measuring 2 x 1.2 metres is a tall order for anyone, but when D2H responded with a composite design that didn’t so much beat our target as obliterate it, we knew we’d made the right decision to commission them.”

– Craig McCarthy

President, Aerodine Composites